In engineering construction, the excavator is the main “steel force”, bear the earth excavation, material handling and other key tasks. However, it also needs regular “physical examination” to ensure good operation. Below, we will talk about the excavator engine heat and air conditioning refrigeration problems of the investigation and maintenance points.

High engine temperature problem: to find out the “overheating culprits”

The engine is the excavator's “heart”, high temperature problems will affect its performance, and even cause serious failures.

· High temperature causes

Fan belt is too loose, coolant shortage or deterioration, water tank internal and external blockage, thermostat failure, water pump damage, engine internal waterway blockage, etc., may lead to high engine temperatures.

· Troubleshooting tips

First check whether the fan belt is too loose, then see whether the coolant is sufficient and whether there is scale, then check whether the water tank is clogged externally, and finally determine whether the thermostat or water pump is damaged.

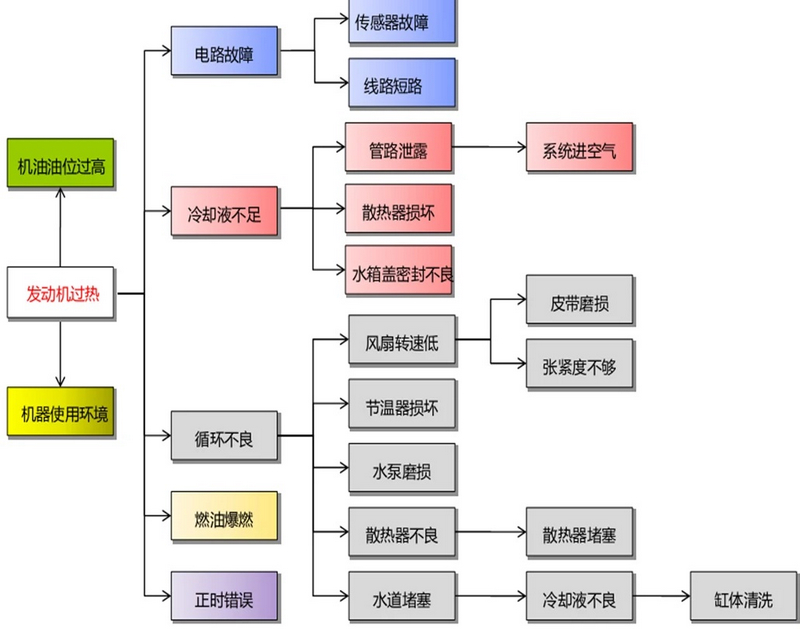

· Fault tree analysis

Constructing the engine high temperature fault tree, with high temperature as the top event and the above factors as the middle and bottom events, connected by logical relationships, can quickly locate the cause of the fault.

Air Conditioning Cooling Effect Problem Identification: Creating a Comfortable Operating Environment

In summer, air conditioners provide a comfortable environment for operators, and poor cooling can affect the operating experience. Regular inspection and maintenance is critical.

· Daily Inspection

If the air conditioner is not used for a long time, turn it on once a month for about 10 minutes each time; for air conditioners with heating function, add antifreeze to the circulating water.

· Regular Maintenance

To ensure stable operation of the air conditioning system, a detailed regular maintenance plan is required. Check whether the refrigerant and compressor are running normally every month, and judge by observing the pressure gauge and listening to the compressor running sound; check whether there are any abnormalities, such as breakage, loosening, etc., in parts such as refrigeration tubes, condenser heat sinks, electromagnetic clutches, wires, connectors and control switches, etc., every six months; annually check whether there are any abnormalities in the joints, drying cylinders, air-conditioning mainframes, body and air-conditioning seals, belts and tightness, and fixing bracket mounting, etc., and ensure that all parts are firmly connected and sealed. Ensure that all parts are firmly connected and well sealed.

· Common troubleshooting

· Refrigeration interruption: change the dry cylinder, vacuum, add refrigerant, repair or replace the temperature sensor.

· Increased noise: adjust or replace the belt, bracket and other parts.

· Insufficient heating: clean up the dampers of foreign objects, wait for the engine cooling water to warm up before turning on the air conditioning, repair or replace the pipeline.

· No refrigeration: check the blower and compressor first, check the refrigerant if it is normal, or check the equipment parts if it is not normal.

· Poor cooling effect: check the air flow, clean the condenser fan, etc., adjust the refrigerant dose or belt, change the filter, clean the heat sink.